Our timber frame design process begins with our clients’ ideas, then we make the idea work structurally, and then we add an elegant style to the design.

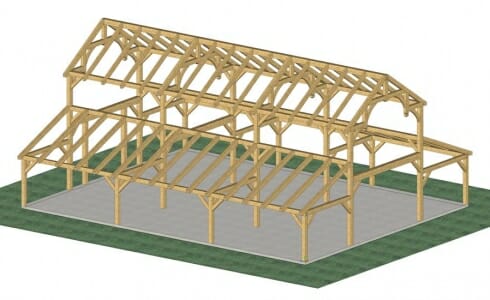

Timber frames are great to incorporate in a building design because they allow for open concept interiors, and the trusses are beautiful and can span great distances at lofty heights like ancient cathedrals

THE DESIGN PROCESS

It’s similar for most projects. Here is how we do it:

- Start with our clients’ construction ideas.

- Draw preliminary pencil sketches for review and pricing.

- Create a 3d model that can be viewed from all directions.

- Run engineering to ensure structural stability.

- Receive final approval from our client.

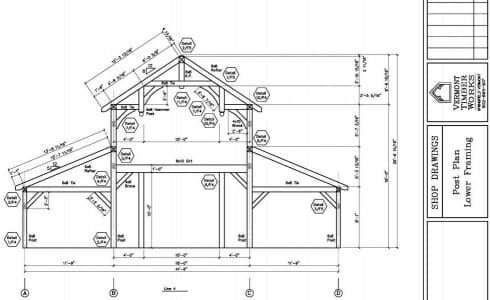

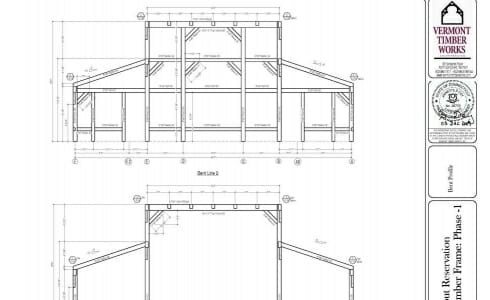

- Draw detailed 2d shop drawings.

- Seal the shop drawings with a stamp from our structural engineering team.

3D MODELS

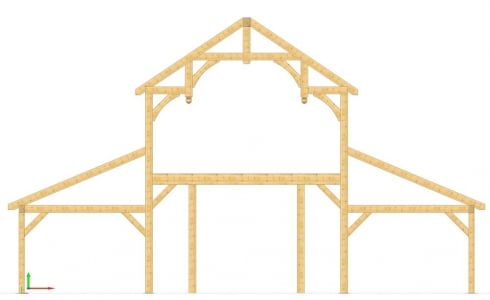

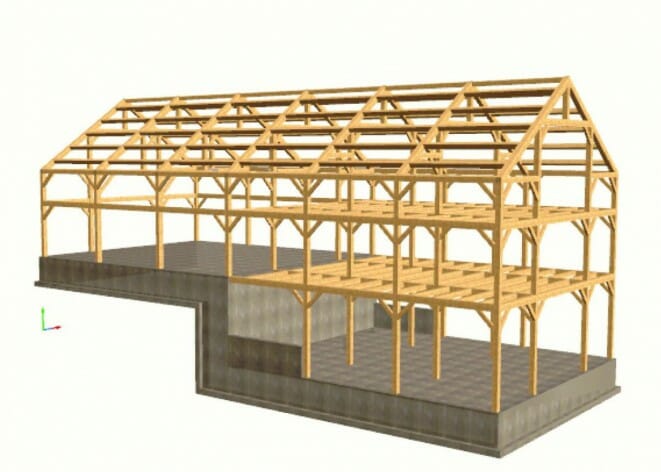

We also render a 3 dimensional model of the timber frame. The model can be viewed from any direction.

The rendering helps us, and the client, visualize the frame during the design process, and get a true feeling of the timber frame before it is built.

3D ModelsSHOP DRAWINGS

Detailed shop drawings are created prior to fabrication. First draft drawings are sent to the client for design review. Then, after they are revised according to the job specifications and get final approval, the drawings are sent to the shop to be used for fabrication.

SHOP DRAWINGS

These are the actual drawings that were used to fabricate the Deer Lake dining hall timber frame.

DEER LAKE DINING HALLFINISHED TIMBER FRAMES

Modified hammer beam trusses in the Trapp Family Lodge in Stowe, VT. The timber is douglas fir with a natural urethane finish

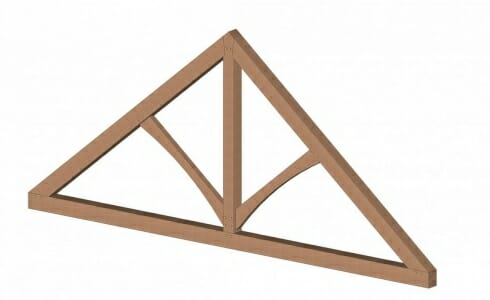

King post trusses can be modified by raising the bottom chord to give a feeling of height. However, raising the bottom chord increases stresses on the top chords, so the timber often needs to be large. For instance, 8x8 top chords on a standard king post truss may have to be increased to 8x12's or 8x14's for a modified king post truss.

This 80' octagon ski lodge in Stowe, VT created a plethora of design and engineering challenges. The snow loads were over 100 pounds per square foot, and the dormers were snow catchers, which causes more dead load. The solution was to was to use sloped double chorded girder trusses and a major steel tension ring around the bottom of the octagon